A Guide To Allen-Bradley PLCs

Allen-Bradley is globally renowned for its innovative spirit and leadership in adopting cutting-edge technologies early on. With a rich history

Allen-Bradley HMIs, or Human Machine Interfaces, play a crucial role in industrial automation by providing operators with a visual representation of the manufacturing process. In this guide article, we will delve into the features, benefits, and applications of Allen-Bradley HMIs, designed to enhance efficiency and productivity in various industries.

The Allen-Bradley PanelView 5000 series of Human Machine Interfaces is designed for seamless integration into control systems; these HMIs offer high-performance visualisation and control capabilities. The PanelView 5000 series boasts a range of screen sizes and resolutions to suit diverse application needs, from compact machines to large processes. With its modern design, multi-touch screen, and intuitive navigation, operators can easily monitor and manage processes efficiently. The HMIs support a wide array of communication options for connectivity with various controllers, enabling real-time data access and control. Additionally, the PanelView 5000 series comes equipped with FactoryTalk ViewPoint software for remote monitoring on mobile devices, enhancing flexibility and productivity.

Designed to cater to a wide range of industrial applications, PanelView Plus 7 Performance series HMIs offer unparalleled functionality and user-friendly features. The Performance series boasts a sleek design coupled with a high-resolution display that provides operators with a crystal-clear view of processes. Its multi-touch screen and intuitive navigation make monitoring and managing operations a breeze, allowing for increased efficiency on the factory floor. Moreover, the PanelView Plus 7 Performance HMIs support various communication protocols, ensuring seamless connectivity with different controllers for real-time data access and control. This series doesn’t just enable monitoring, but also allows remote monitoring on mobile devices via FactoryTalk ViewPoint software, giving users greater operational flexibility and boosting productivity.

With a user-friendly interface and robust functionality, these HMIs are designed to streamline operations and enhance productivity on the factory floor. The Standard series features a range of screen sizes to suit different applications and environments, providing operators with clear visibility of processes and machine status. Equipped with Ethernet and USB ports, these HMIs facilitate easy connectivity for data transfer and system integration. The PanelView Plus 7 Standard HMIs support a variety of communication protocols, ensuring compatibility with a wide range of controllers for seamless data access and control. Whether it’s monitoring production metrics or troubleshooting issues, the Standard series empowers users with the tools they need to effectively manage operations. Additionally, with options for remote monitoring and management, operators can stay connected and make informed decisions even when away from the plant floor.

Allen-Bradley’s PanelView 800 series of HMIs are equipped with a user-friendly interface that allows operators to easily navigate through data and applications, providing real-time insights into production metrics and machine status. With Ethernet and USB ports, the PanelView 800 HMIs ensure seamless connectivity for data transfer and integration with other systems. Supporting a wide range of communication protocols, these HMIs enable compatibility with various controllers, offering flexibility and ease of use for operators. Whether monitoring production processes or troubleshooting issues, the PanelView 800 series empowers users with the tools needed for effective operations management.

You can view Mizen Automation’s full range of Allen-Bradley automation parts here.

Allen-Bradley is globally renowned for its innovative spirit and leadership in adopting cutting-edge technologies early on. With a rich history

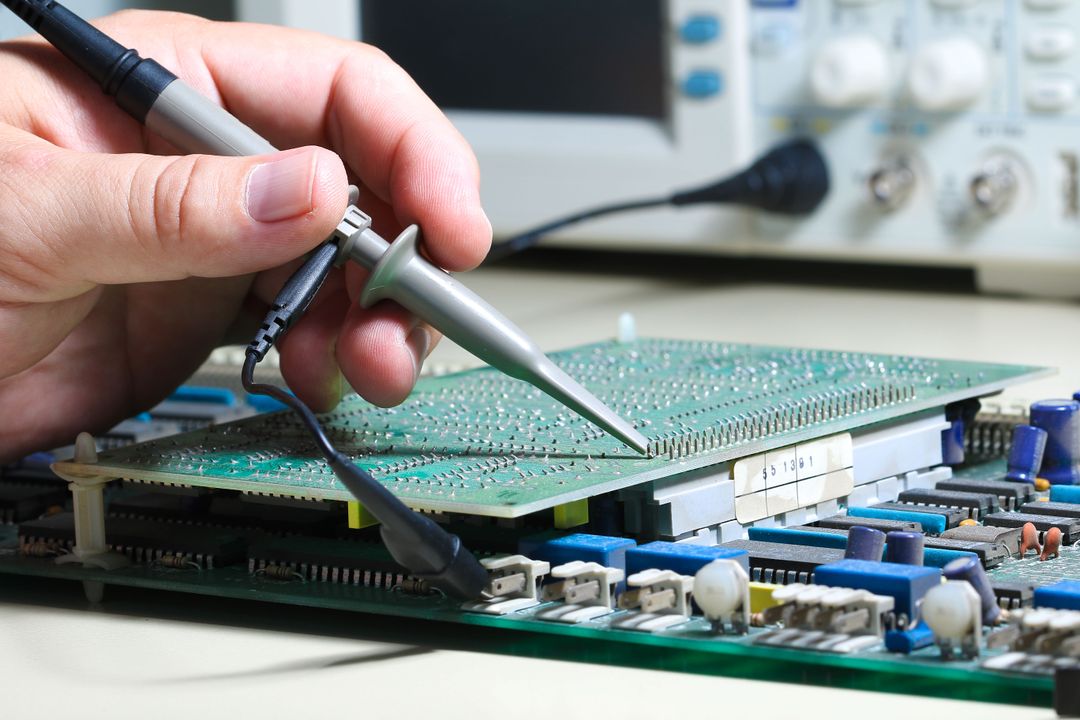

Repairing hardware is more sustainable than replacing it. It reduces waste, saves resources, saves money and creates jobs. By adopting

If you have any questions get in contact with us via our enquiry form or call us on +64 (0) 3 964 0692.